|

|

Millstones |

|

|

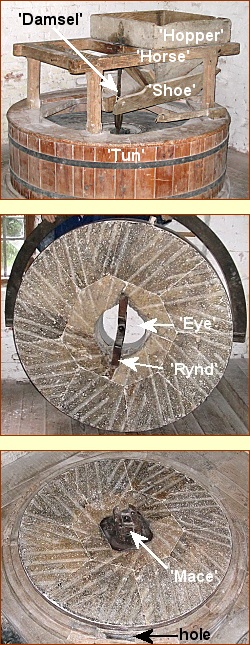

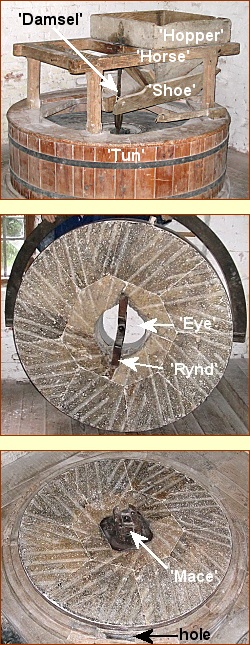

The millstones

in use, each 52.5" (133 cm) in diameter, are surrounded by a wooden

cover or 'tun', with the 'horse' supporting the 'hopper' and 'shoe'.

When operated commercially, grain fell from a grain bin in the Garner,

through a chute into the 'hopper', then slowly fed into the grain

'shoe'. This is agitated by the 'damsel', an iron rod located on the top

of the 'rynd'. Grain shaken from the 'shoe' falls into the central 'eye'

of the upper or 'runner' stone to be milled into wholemeal flour as it

moves to the outer edge of the stones. |

| The middle

picture shows the 'runner' stone being held on edge by the stone

crane. It enables stones, weighing up to a ton, to be lifted and

inverted to clean or dress the stone. The 'runner' and the 'bed' stone

are 'French' stones, each created from a number of pieces of hard

flint-like stone, or burrs, that were quarried near Paris. Specialised

stone masons would select a number of burrs before cutting them to

produce the millstones, holding them together by circular iron bands and

plaster of paris. The iron 'bar' or 'rynd' across the central 'eye' fits

over the 'mace' on the stone spindle, balanced on the pivot point of the

spindle, and turns the stone as the spindle rotates. Before being used,

a new runner stone needs to be balanced to run smoothly by placing small

lead weights into shallow holes in the top plaster surface. This runner

stone is made from thirteen burrs with four inner and nine outer pieces.

Many stones are made using more burrs, the open runner stone on the

Stone Floor being made from 24 burrs. |

| The bottom

picture shows the bed stone, fixed in position on the Stone Floor, and

surrounded by the close-fitting wooden skirting. A hole in the skirting,

but inside the surrounding 'tun', allows the meal produced by the

millstones to fall down a chute to the Meal

Bagging area on the floor below. The stone spindle protrudes through

the center of the bed stone and is fitted with the thick cast-iron 'H'

shaped 'mace', kept in position by the weight of the runner stone. The

spindle emerges through the mace to form the pivot point upon which the

'rynd' and runner stone rest. This bed stone is made from four inner and

eight outer burrs. |